Sanitary gaskets play a crucial role in food and beverage processing systems, ensuring hygienic and efficient operations. Selecting the right gasket requires precise understanding of material properties, compliance with hygiene standards, and compatibility with varying process conditions. Whether you’re sourcing from a wholesale sanitary gasket supplier or a sanitary gasket manufacturer, choosing the best fit is crucial to ensuring long-lasting performance and reliability.

Índice de contenidos:

Key Factors When Selecting Sanitary Gasket Materials for Food-Grade Use

Why EPDM and Silicone Sanitary Gaskets Are Popular in Beverage Systems

Understanding Hygiene Standards in Sanitary Sealing Solutions

The right gasket not only prevents leaks but also upholds safety and hygiene in every pipeline connection, particularly in industries like food, beverage, and pharmaceuticals where cleanliness is paramount. By selecting high-quality gaskets tailored to your specific needs, you can enhance efficiency, reduce maintenance costs, and ensure compliance with industry standards.

Key Factors When Selecting Sanitary Gasket Materials for Food-Grade Use

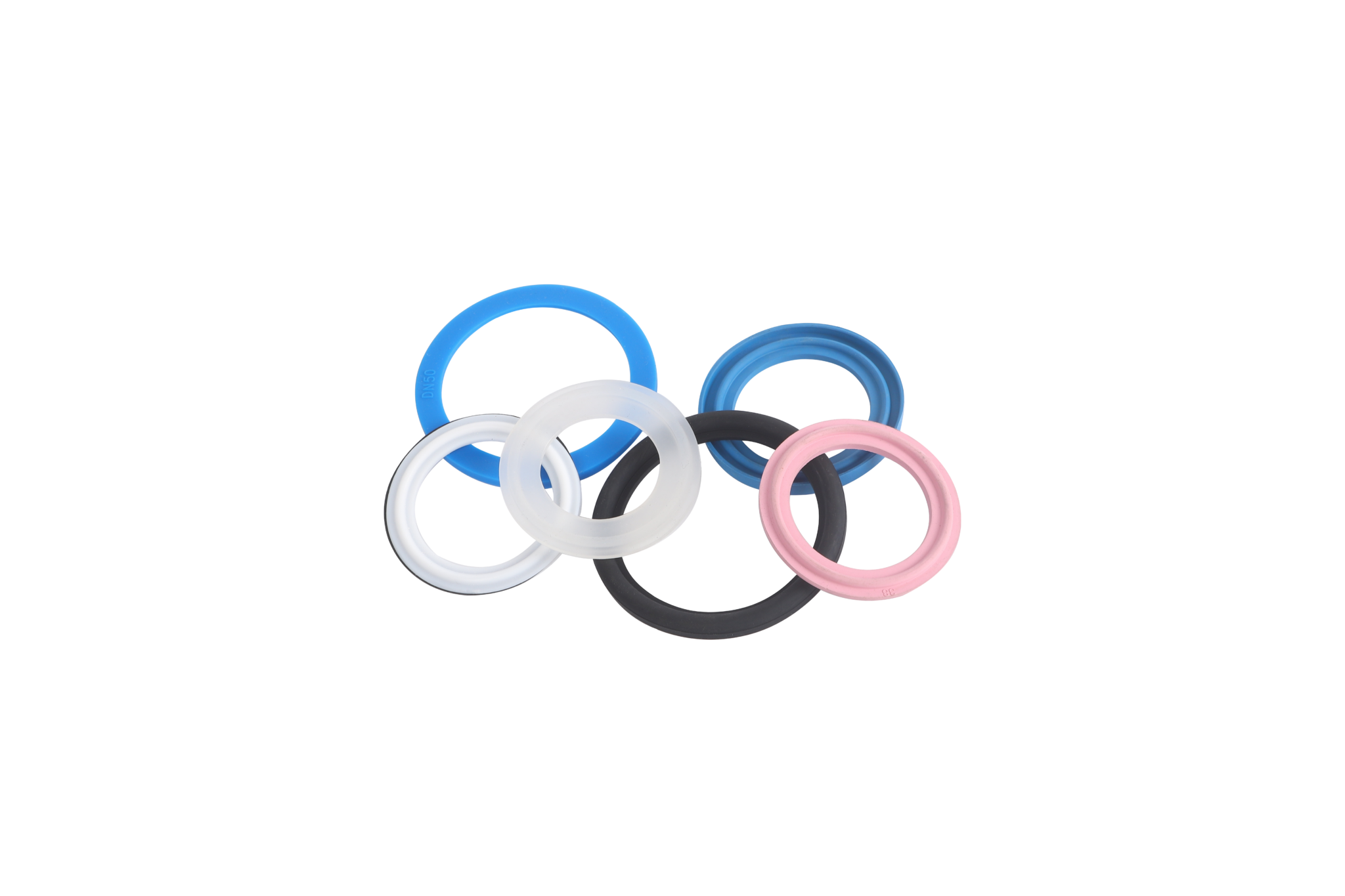

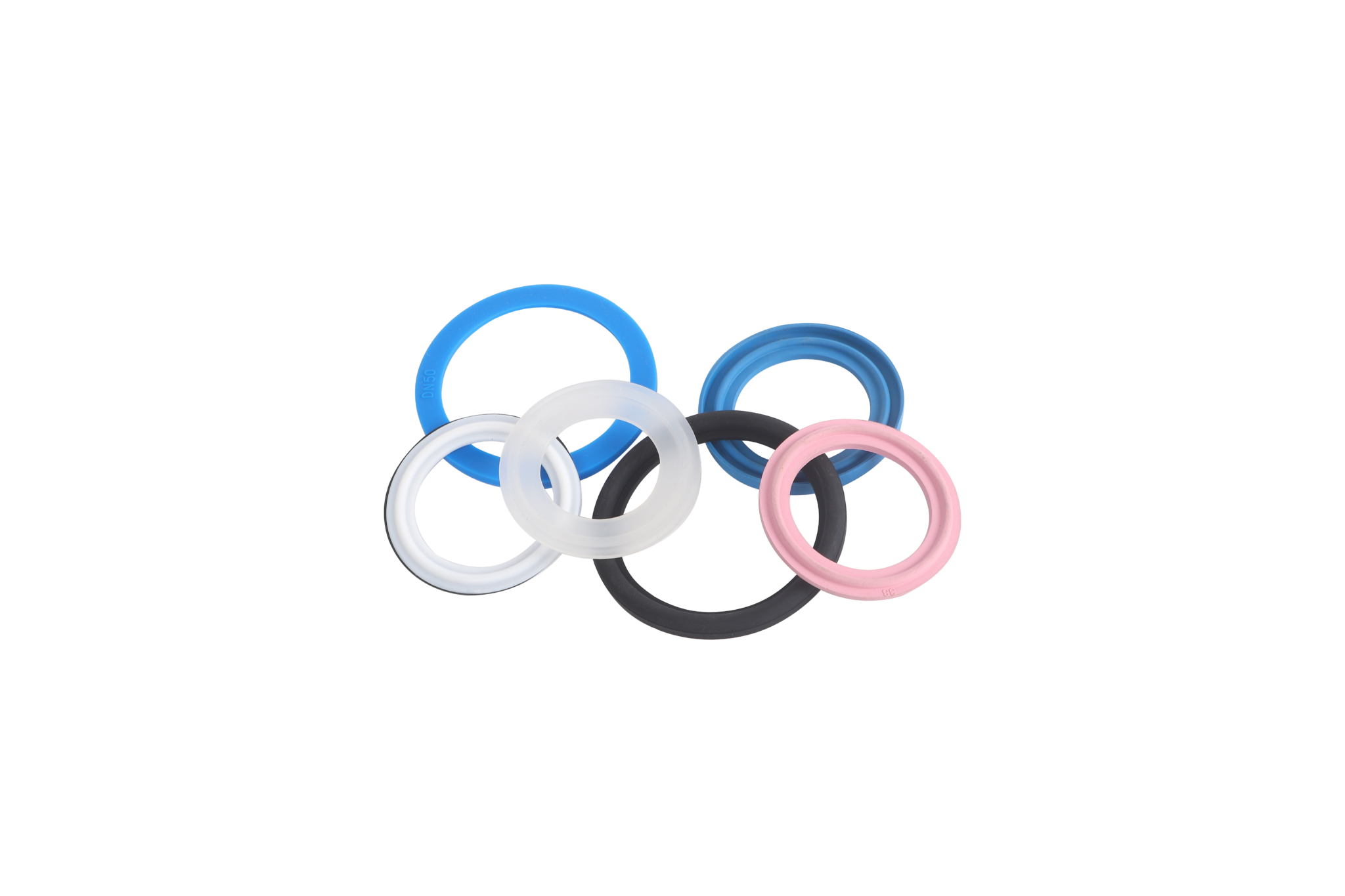

When choosing sanitary gaskets, material compatibility should top your checklist. Food and beverage applications often deal with varying temperatures, pressures, and chemicals, making it essential to select high-quality gaskets designed to perform under these demanding conditions. Materials like PTFE, EPDM, silicone, and Viton are commonly used due to their superior durability and chemical resistance. PTFE gaskets, for example, are non-reactive, making them suitable for strong acids or harsh cleaning chemicals. EPDM, known for its flexibility, remains a reliable choice for maintaining good sealing under pressure. Silicone gaskets excel in extreme temperature ranges, and Viton ensures resistance against oil, solvents, and other industrial fluids. A suitable gasket material should not only offer high performance but also comply with relevant food-grade safety standards, ensuring hygienic processing and reduced contamination risks.

Why EPDM and Silicone Sanitary Gaskets Are Popular in Beverage Systems

EPDM and silicone sanitary gaskets have risen in popularity in modern food and beverage systems for offering highly specific technical advantages. EPDM sanitary gaskets stand out because of their exceptional resistance to heat, steam, and a wide range of cleaning and sanitizing chemicals. This combination makes them highly effective in systems that undergo constant washing, sterilization, or exposure to both acidic and basic solutions. On the other hand, silicone gaskets maintain excellent sealing properties in applications requiring both high heat resistance and elasticity. Silicone is commonly chosen to ensure that no taste or odor is imparted into beverages during processing. With sizes ranging from DN15 to DN150, both EPDM and silicone gaskets from renowned sanitary gasket manufacturers like those offered on HongtaiValve can be customized to suit various system designs. Furthermore, they contribute to leak-free performance, enabling smooth, contamination-free production in beverage pipelines.

Understanding Hygiene Standards in Sanitary Sealing Solutions

Sanitary gaskets used in food and beverage applications must adhere strictly to industry hygiene standards. Standards like FDA compliance and 3A Sanitary Standards ensure the gasket material is fit for contact with consumable goods without compromising safety. FDA-compliant gaskets, for instance, are composed of materials that are non-toxic, resistant to bacterial growth, and inert under typical food or beverage processing conditions. For companies sourcing gaskets, sanitary gasket manufacturers that provide certifications for their EPDM, PTFE, silicone, or Viton gaskets ensure both the reliability and legitimacy of their products. PTFE gaskets, revered for their temperature and chemical tolerance, also meet high hygiene standards, further reducing risk in facilities with strict regulatory compliance requirements. Whether you’re purchasing wholesale sanitary gaskets or specific trims like tri-clamp or flanged gaskets, understanding these standards is key to making choices that protect your system and the end-consumer.

Choosing the right sanitary gaskets requires careful consideration of their material properties, adherence to hygiene standards, and the specific demands of your application. With experienced sanitary gasket manufacturers offering high-grade options like EPDM, PTFE, silicone, and Viton, businesses can ensure production systems operate efficiently, hygienically, and reliably. Relying on wholesale sanitary gasket procurement also allows companies to streamline their supply chain while standardizing performance. For seamless performance in your pipeline systems, always prioritize quality, compatibility, and recognized compliance standards when selecting gaskets. Make informed decisions today and ensure your business secures long-lasting, efficient sealing solutions for food and beverage applications.