Sanitary gaskets are an essential component in industries requiring high hygiene standards such as food production, pharmaceuticals, and chemicals. These seemingly simple components play a critical role in ensuring efficiency, promoting sterile processes, and reducing downtime across hygienic systems. Wholesale sanitary gaskets, manufactured to precise standards, are more than just seals; they are a crucial factor in system longevity and performance. This article will explore how sanitary gaskets contribute to process efficiency, focusing on their durability, precision fit, and reliability in dynamic flow conditions.

目录

Minimizing Downtime with Durable, Long-Life Gasket Materials

Gasket Fit and Surface Smoothness: Why Precision Matters

Maintaining Sterile Seals in Dynamic Flow Conditions

Enhance Efficiency with Quality Sanitary Gaskets

Minimizing Downtime with Durable, Long-Life Gasket Materials

One of the key factors for maintaining efficiency in a hygienic process system is minimizing downtime during operations. Sanitary gaskets made from durable materials like PTFE, EPDM, silicone, and Viton are specifically designed to stand up to harsh operating conditions. These materials are resistant to extreme temperatures, chemicals, and wear, making them well-suited for use in demanding environments. For example, gaskets like PTFE can handle temperatures ranging from -196°C to +250°C, offering consistent performance in both freezing and high-heat setups. Their resistance to chemical corrosion is another advantage, ensuring that even the most aggressive cleaning agents or process chemicals won’t degrade seals prematurely. This durability reduces the frequency of gasket replacements, minimizing disruptions and ensuring the seamless operation of the system. For industries where hygiene interruptions equate to production losses, these long-lasting gasket materials play an invaluable role.

Gasket Fit and Surface Smoothness: Why Precision Matters

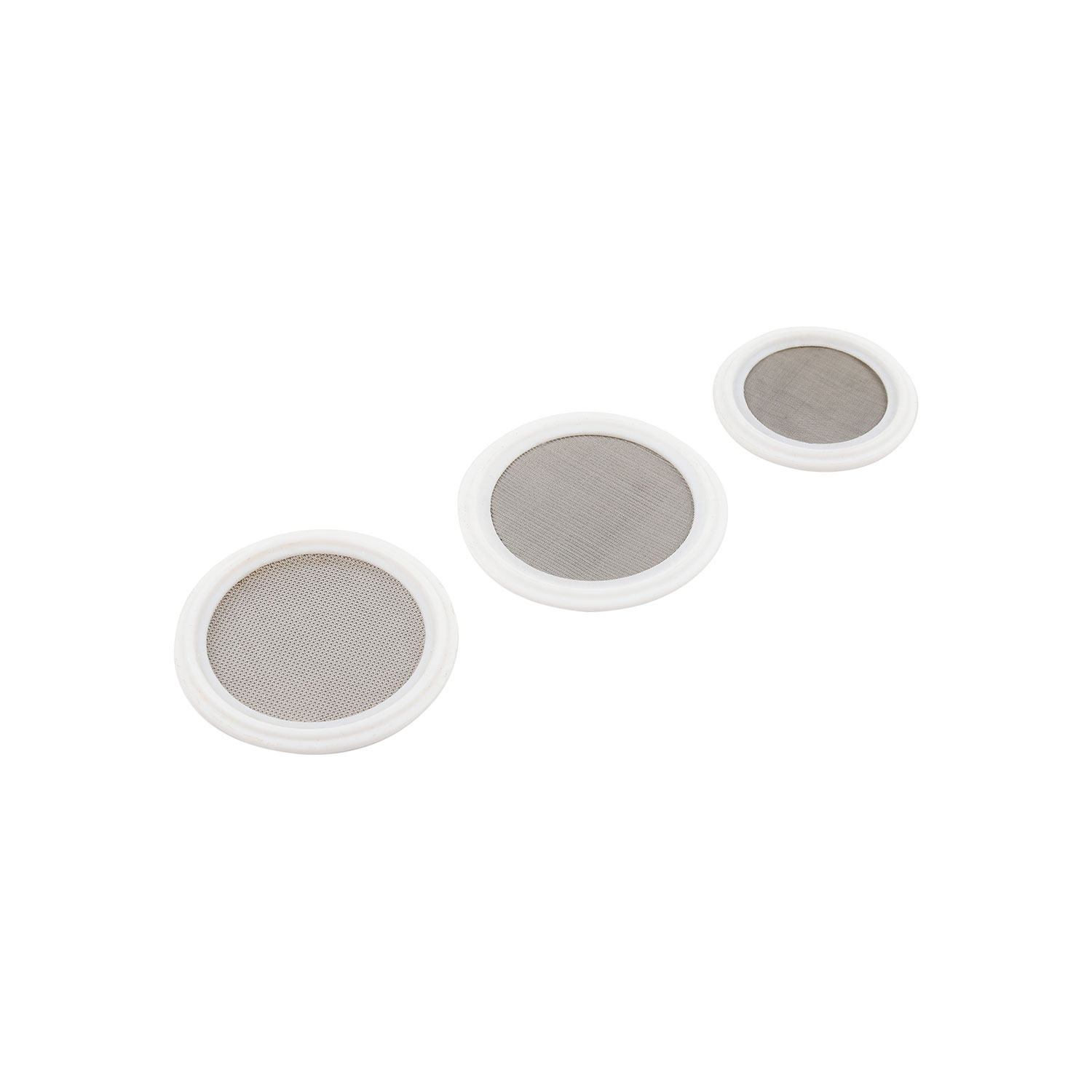

The fit and surface smoothness of a gasket are equally instrumental in ensuring process efficiency. A poorly fitted gasket can lead to leaks, contamination risks, or inefficiencies in a sanitary process. Precision-engineered gaskets, like those produced by leading sanitary gasket manufacturers, are designed to create a leak-proof seal between tri-clamp flanges, ensuring no material escapes or enters the pipeline. Additionally, the smoothness of their surfaces is vital to prevent residue buildup and bacterial growth, which can compromise hygiene. High-quality gaskets meet strict industry standards such as 3A and FDA certifications, ensuring excellent sealing performance while aligning with sanitation regulations. For example, the sanitary gaskets offered at HongTai Valve are crafted with advanced technology to provide optimal surface accuracy and tight tolerances, yielding a superior seal every time. A precise fit also facilitates easy installation and maintenance, saving effort and resources while ensuring continuous productivity.

Maintaining Sterile Seals in Dynamic Flow Conditions

Dynamic processing conditions, including fluctuating temperatures and varying flow rates, require gaskets that can maintain their sealing capability even under strain. Sanitary gaskets offer the perfect solution for such challenges. These gaskets are capable of preserving a sterile, leak-proof seal despite the effects of expanding and contracting piping systems, frequent cleaning cycles, or changes in pressure levels. Materials such as silicone and Viton are particularly effective in these scenarios, providing flexibility and consistent performance while maintaining their hygienic integrity. For industries where sterile environments are non-negotiable, such as pharmaceutical manufacturing or food production, these gaskets are indispensable. They prevent cross-contamination and product loss, which are critical concerns when producing consumables. Investing in the right type of sanitary gasket, sourced from a trusted manufacturer like HongTai Valve, ensures peace of mind with dependable results in dynamic conditions.

Enhance Efficiency with Quality Sanitary Gaskets

Sanitary gaskets are the unsung heroes of hygienic process systems, providing durability, precision, and reliability in the most demanding environments. They are vital for minimizing downtime, ensuring a precise fit, and maintaining sterile seals in challenging flow conditions. Whether you operate a food production line or manage a pharmaceutical facility, investing in high-quality wholesale sanitary gaskets from a reputable sanitary gasket manufacturer ensures long-lasting efficiency and compliance with hygiene standards.

When it comes to selecting performance-driven sanitary gaskets, HongTai Valve offers a robust selection of PTFE, silicone, EPDM, and Viton gaskets designed to withstand the rigors of modern hygienic processes. Contact HongTai Valve today to find the perfect solution for your operations and experience how top-tier sanitary gaskets can transform your system’s efficiency and reliability.