Mô tả

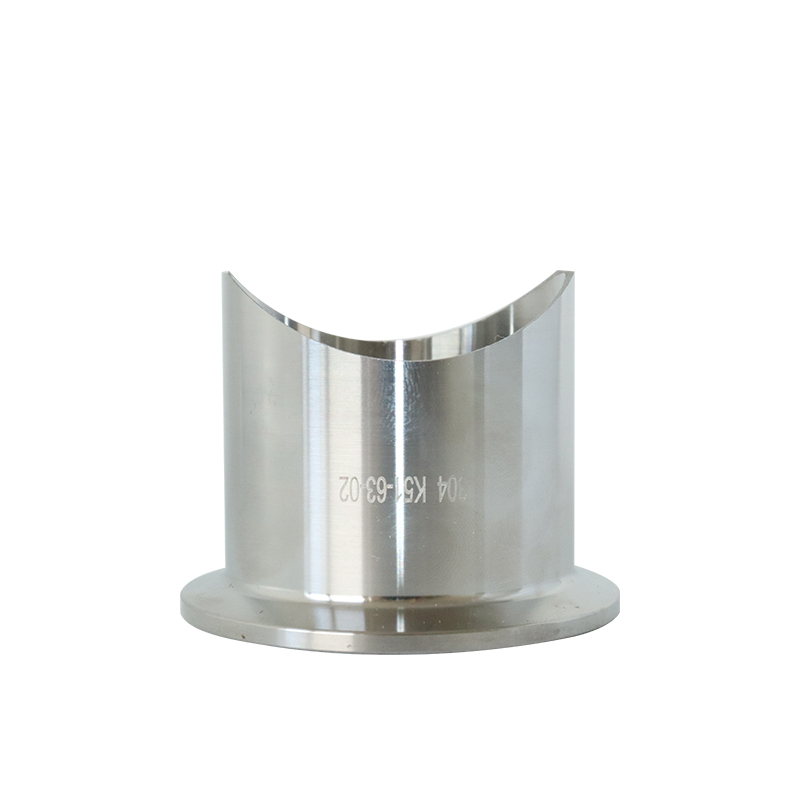

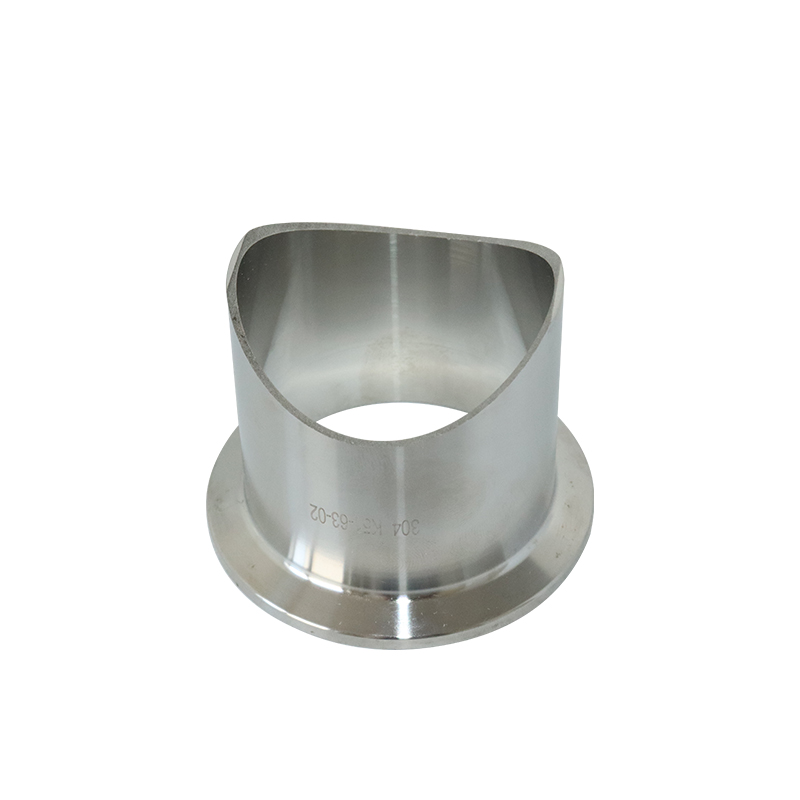

Non-Standard Customized Stainless Steel Food-Grade Piping Components | High-Purity Fluid Transfer Solutions

——

Product Overview

Designed specifically for the food & beverage, pharmaceutical, and dairy industries, our316L/304 stainless steel non-standard piping custom componentsprovide a high-purity, corrosion-resistant fluid transfer system. Supporting custom shapes and structures, they meet the needs of complex process layouts and are compatible with CIP/SIP cleaning standards, ensuring zero residue of media.

——

Core Advantages

1. Precision Piping Connection Technology

• Tri-Clamp Quick-Connect (Clamp Type): ISO 2852 standard, quick assembly and disassembly, sealing materials available in EPDM, silicone, or PTFE, temperature resistance from -50℃ to 200℃.

• Automatic/Manual Welding Interfaces: No weld bead protrusion on the inner wall, consistent diameter, avoiding media stagnation.

2. Full-Process Non-Standard Customization Capability

• Custom Shapes: Elbows (30°~180°), reducers, tees/crosses, U-bends, etc., customized as needed.

• Flexible Sizes: Pipe diameter range from DN15 to DN500 (1/2″ to 20″), wall thickness adjustable from 0.5mm to 5mm, suitable for high-pressure or vacuum systems.

3. Food-Grade Stainless Steel Material

• 316L ultra-low carbon stainless steel (resistant to intergranular corrosion), certified by ASTM A270, tolerant of acids, bases, alcohol, and high-temperature steam.

4. Internal and External Mirror Polishing Process

• Electrolytic Polishing: Inner wall Ra≤0.4μm, outer wall Ra≤0.8μm, complying with EHEDG/3-A hygiene standards, preventing microbial growth.

• Passivation Treatment: Enhances surface oxidation resistance, extending pipe lifespan.

——

Industry Application Scenarios

IndustryTypical UsesCustomization Focus

Beer BrewingFermentation tank piping, wort transfer pipes, CIP return pipesResistant to hop acid corrosion, large-radius elbow design

Beverage ProductionSyrup distribution pipes, carbonated water injection lines, aseptic filling systemsHigh-gloss inner wall, anti-crystallization structure

Pharmaceutical IndustryPurified water piping, bioreactor connections, aseptic liquid preparation systemsFully automatic orbital welding, zero-dead-space connections

Dairy Processing Pasteurization piping, cream transfer pipes, milk tank connectors Resistant to 150℃ high-temperature steam, quick-disconnect cleaning design

——

Non-Standard Customization Service Process

1. Needs Assessment: Provide process flow diagrams or 3D drawings, indicating media, pressure, temperature, and other parameters.

2. Design Optimization: Engineers evaluate structural reasonability and suggest modular solutions to reduce welding points.

3. Sample Confirmation: Deliver prototypes within 15 working days, supporting on-site dimension verification.

4. Mass Production: Utilize laser cutting/hydraulic forming processes to ensure a tolerance of ±0.1mm.

——

Recommended Ancillary Components

• Valves: Sanitary ball valves, diaphragm valves (Tri-Clamp connections).

• Instruments: Temperature sensors, flow meters (Hastelloy material).

• Supports: Adjustable pipe clamps, anti-vibration brackets (304 stainless steel).

——

Why Choose Us?

• Industry Expertise: 10 years focused on food and pharmaceutical piping customization, with over 200 successful cases.

• Rapid Response: Emergency orders delivered in 7 days, supporting small-batch trials.

• Quality Assurance Commitment: 18-month extended warranty, lifetime maintenance support.

——

Keywords: Food-grade stainless steel piping, non-standard customized piping components, Tri-Clamp quick-connect piping, pharmaceutical clean piping, 316L mirror-polished piping, dairy processing piping systems.

Product Packaging Instructions:

Each product is first individually packaged in a foam bag, then carefully placed into a designated carton. Finally, it is palletized or packed in an export wooden crate. The entire packaging process is rigorously executed to prevent any damage during transportation.

About us

At HongTai, we specialize in high-quality sanitary valves and stainless steel pipe fittings,serving key industries such as pharmaceuticals, food processing, and chemicals. Made from premium 304, 316, and 316L stainless steel, our products offer excellent corrosion resistance and are crafted using advanced manufacturing techniques like laser cutting and precision welding. Designed for hygiene and fluid integrity, HongTai’s valves are the ideal choice for industries requiring optimal cleanliness and long-lasting performance.

Why Choose Us

Quality Assurance: We maintain strict control over every production stage, from raw materials to finished products, ensuring compliance with ISO9001 and international certifications, including 3A, DIN, and ISO standards.

Industry Expertise: Decades of experience in providing solutions for critical industries like food, beverage, and pharmaceuticals.

Advanced Technology: Our state-of-the-art facilities, including regularly updated CNC lathes and precision tools, guarantee high surface accuracy and tight tolerances for every product.

100% Inspection: Every product undergoes rigorous testing, including size and valve leak detection, to ensure flawless quality before it leaves our facility.

Global Reach: Trusted by businesses around the world for our consistent quality and on-time delivery.

Choose HongTai for unmatched reliability, performance, and innovation in valve and pipe fitting solutions.

Contact us

For more information or to discuss your requirements, reach out to us via:

Email: ht@htcdf.com

whatsapp: (86)18875809195

You can also visit our Contact Us page for more ways to get in touch.

Đánh giá

Chưa có đánh giá nào.