说明

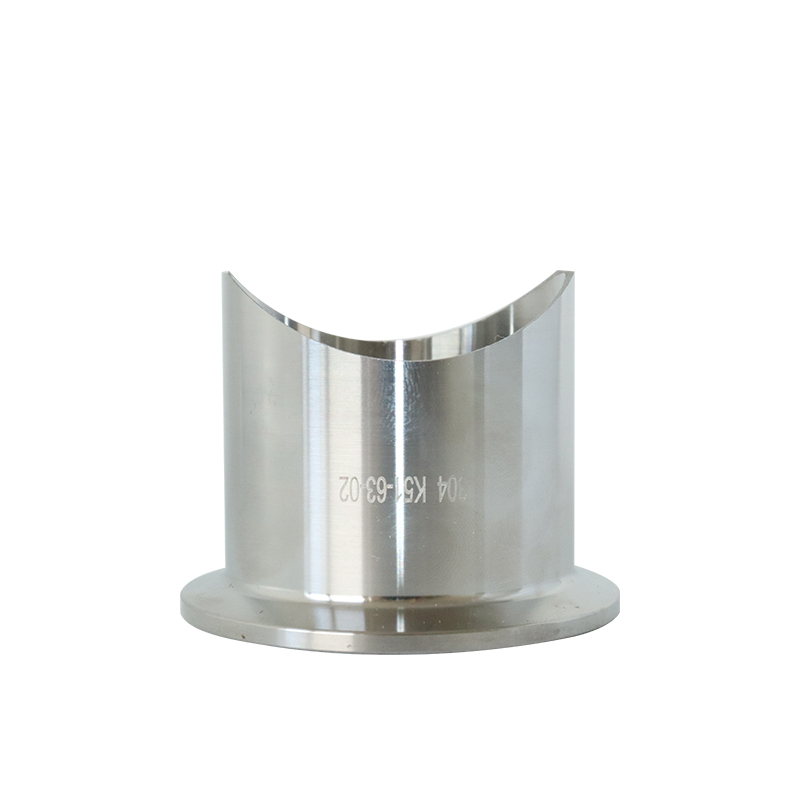

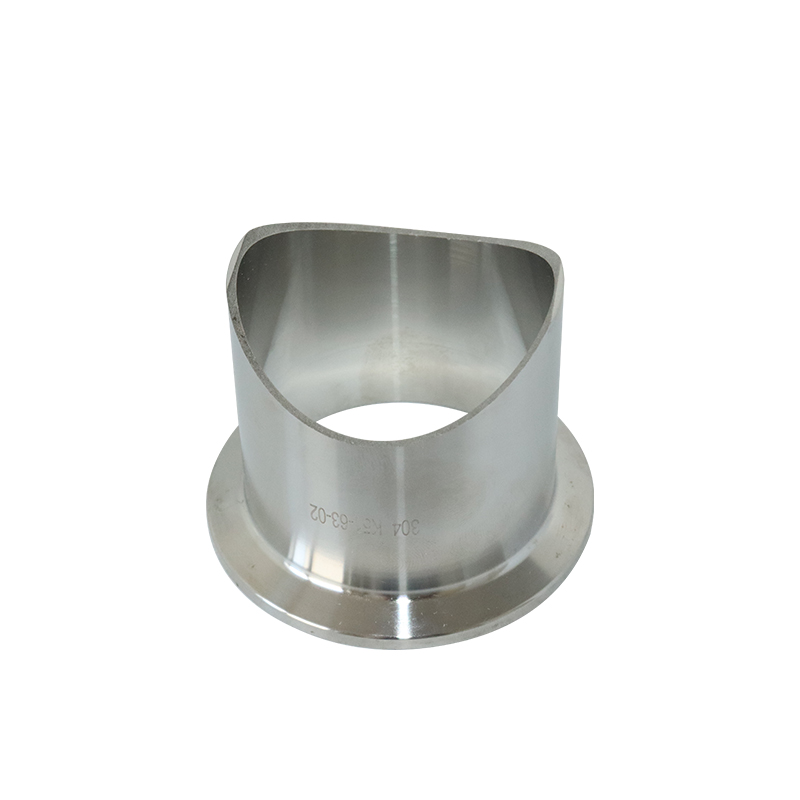

Non-Standard Customized Stainless Steel Food-Grade Piping Components | High-Purity Fluid Transfer Solutions

——

Product Overview

Designed specifically for the food & beverage, pharmaceutical, and dairy industries, our316L/304 stainless steel non-standard piping custom componentsprovide a high-purity, corrosion-resistant fluid transfer system. Supporting custom shapes and structures, they meet the needs of complex process layouts and are compatible with CIP/SIP cleaning standards, ensuring zero residue of media.

——

Core Advantages

1. Precision Piping Connection Technology

• Tri-Clamp Quick-Connect (Clamp Type): ISO 2852 standard, quick assembly and disassembly, sealing materials available in EPDM, silicone, or PTFE, temperature resistance from -50℃ to 200℃.

• Automatic/Manual Welding Interfaces: No weld bead protrusion on the inner wall, consistent diameter, avoiding media stagnation.

2. Full-Process Non-Standard Customization Capability

• Custom Shapes: Elbows (30°~180°), reducers, tees/crosses, U-bends, etc., customized as needed.

• Flexible Sizes: Pipe diameter range from DN15 to DN500 (1/2″ to 20″), wall thickness adjustable from 0.5mm to 5mm, suitable for high-pressure or vacuum systems.

3. Food-Grade Stainless Steel Material

• 316L ultra-low carbon stainless steel (resistant to intergranular corrosion), certified by ASTM A270, tolerant of acids, bases, alcohol, and high-temperature steam.

4. Internal and External Mirror Polishing Process

• Electrolytic Polishing: Inner wall Ra≤0.4μm, outer wall Ra≤0.8μm, complying with EHEDG/3-A hygiene standards, preventing microbial growth.

• Passivation Treatment: Enhances surface oxidation resistance, extending pipe lifespan.

——

Industry Application Scenarios

IndustryTypical UsesCustomization Focus

Beer BrewingFermentation tank piping, wort transfer pipes, CIP return pipesResistant to hop acid corrosion, large-radius elbow design

Beverage ProductionSyrup distribution pipes, carbonated water injection lines, aseptic filling systemsHigh-gloss inner wall, anti-crystallization structure

Pharmaceutical IndustryPurified water piping, bioreactor connections, aseptic liquid preparation systemsFully automatic orbital welding, zero-dead-space connections

Dairy Processing Pasteurization piping, cream transfer pipes, milk tank connectors Resistant to 150℃ high-temperature steam, quick-disconnect cleaning design

——

Non-Standard Customization Service Process

1. Needs Assessment: Provide process flow diagrams or 3D drawings, indicating media, pressure, temperature, and other parameters.

2. Design Optimization: Engineers evaluate structural reasonability and suggest modular solutions to reduce welding points.

3. Sample Confirmation: Deliver prototypes within 15 working days, supporting on-site dimension verification.

4. Mass Production: Utilize laser cutting/hydraulic forming processes to ensure a tolerance of ±0.1mm.

——

Recommended Ancillary Components

• Valves: Sanitary ball valves, diaphragm valves (Tri-Clamp connections).

• Instruments: Temperature sensors, flow meters (Hastelloy material).

• Supports: Adjustable pipe clamps, anti-vibration brackets (304 stainless steel).

——

为什么选择我们?

• Industry Expertise: 10 years focused on food and pharmaceutical piping customization, with over 200 successful cases.

• Rapid Response: Emergency orders delivered in 7 days, supporting small-batch trials.

• Quality Assurance Commitment: 18-month extended warranty, lifetime maintenance support.

——

Keywords: Food-grade stainless steel piping, non-standard customized piping components, Tri-Clamp quick-connect piping, pharmaceutical clean piping, 316L mirror-polished piping, dairy processing piping systems.

产品包装说明

每件产品首先用泡沫袋单独包装,然后小心翼翼地放入指定的纸箱。最后,装入托盘或出口木箱。整个包装过程都是严格执行的,以防止在运输过程中出现任何损坏。

关于我们

宏泰专业生产高品质的卫生级阀门和不锈钢管件,主要服务于制药、食品加工和化工等行业。我们的产品采用优质 304、316 和 316L 不锈钢制成,具有出色的耐腐蚀性,并采用激光切割和精密焊接等先进制造技术精心制作而成。HongTai 的阀门专为卫生和流体完整性而设计,是要求最佳清洁度和持久性能的行业的理想选择。

为什么选择我们

质量保证: 我们严格控制从原材料到成品的每个生产阶段,确保符合 ISO9001 和国际认证,包括 3A、DIN 和 ISO 标准。

行业专长: 数十年为食品、饮料和制药等关键行业提供解决方案的经验。

先进技术: 我们拥有最先进的设备,包括定期更新的数控车床和精密工具,确保每件产品都具有较高的表面精度和较小的公差。

100% 检验: 每件产品在出厂前都要经过严格的测试,包括尺寸和阀门泄漏检测,以确保质量完美无瑕。

覆盖全球: 我们以始终如一的质量和准时交货赢得了全球企业的信赖。

选择 HongTai,您将在阀门和管件解决方案方面获得无与伦比的可靠性、性能和创新性。

联系我们

如需了解更多信息或讨论您的要求,请通过以下方式联系我们:

电子邮件:ht@htcdf.com

whatsapp:(86)18875809195

您还可以访问我们的 联系我们 页面获取更多联系方式。

评论

目前尚无评论。