说明

**EPDM Sanitary Sampling Valve Nipple | 3-A & USP Class VI Certified for Aseptic Bioprocessing**

*CIP/SIP-Ready Fluid Transfer Interface with 135°C Steam Sterilization*

<div style="”border:" 1px solid #e0e0e0; padding: 1rem; margin: 1.2rem 0; background: #f8f9fa;”>

🔍 **Core SEO Keywords**:

“EPDM sanitary sampling nipple”, “3-A compliant valve accessory”, “biopharma steam-sterilizable connector”, “zero dead leg WFI system”, “USP <800> compliant fittings”

</div>

### 🧪 Technical Specifications (ASME BPE Alignment)

| **Parameter** | **Specification** |

|————————|——————————————–|

| **Material** | FDA 21 CFR §177.2600 EPDM (USP Class VI) |

| **Surface Finish** | Ra ≤0.5μm (EHEDG Type EL Class I) |

| **Pressure Rating** | 10 bar @20°C / 4 bar @135°C |

| **Connection Types** | Tri-Clamp (ISO 2852) / DIN 11851 / SMS 1145|

| **Certifications** | 3-A 45-05, ISO 9001:2015, ASTM E2500 |

—

### 🛠️ Engineering Advantages Over Silicone Plugs

✅ **Dual-Shore Hardness Technology**

– **70 Shore A Base**: 20% vibration reduction in HTST/UHT systems (vs. rigid connectors)

– **90 Shore A Tip**: 3x puncture resistance vs silicone for single-use bag adapters

✅ **Biofilm Prevention System**

– Electropolished 316L stainless steel insert

– Full drainage tangential flow path

✅ **Chemical Resilience**

– 100+ CIP cycles with 4% HNO₃/2% NaOH

– WFI/ethanol/polar solvent compatible

—

### 🌐 Industry Applications & Compliance Matrix

| **Sector** | **Use Case** | **Standard Met** |

|——————|———————————————|—————————|

| **Biopharma** | USP <797> bioreactor sampling | FDA cGMP, ICH Q7 |

| **Dairy** | Homogenizer discharge monitoring | 3-A 74-06, IDF 2014 |

| **Beverage** | High-acid product testing (pH<4.5) | EHEDG Module 26 |

| **WFI Systems** | Water for injection distribution loops | USP <1231>, PW/HPW Tier 1 |

—

### ⚙️ Installation & Maintenance Features

▸ **15-Second Tool-Free Assembly**

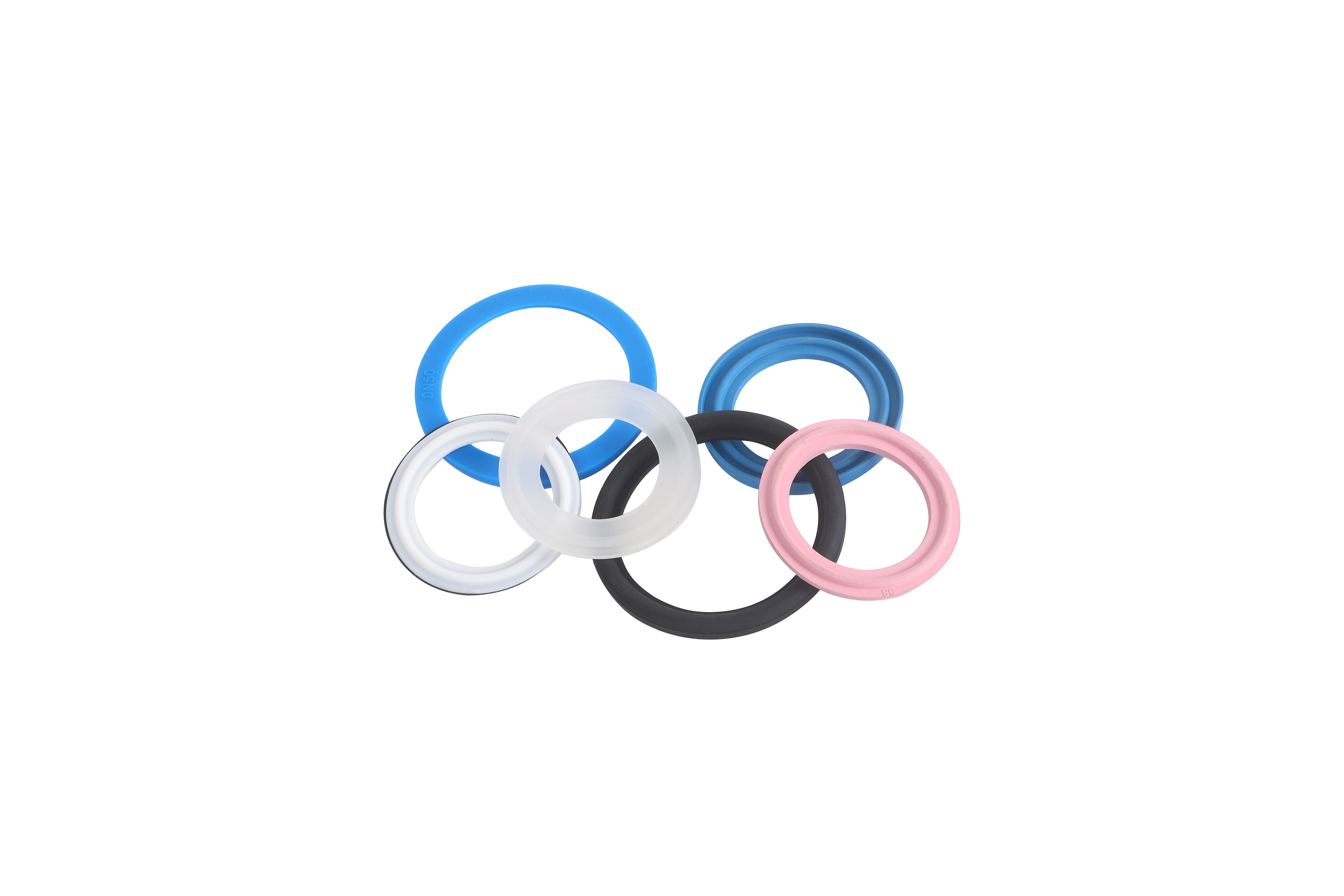

– Color-coded blue EPDM band (ASME BPE SD-5.1 compliance)

– Integrated torque indicator grooves

▸ **Autoclavable & Traceable**

– 500+ steam cycles @135°C validation data available

– Laser-etched material batch ID + QR code linkage

▸ **Spare Parts Compatibility**

– Interchangeable with Varivent®/BioQuate® flange systems

—

**SEO-Driven Content Strategy**

1. **Header Hierarchy**: Focus on question-based semantics (How/Why/What)

– H2: “How Does EPDM Outperform Silicone in Steam Sterilization?”

– H3: “Solving 3 Major Contamination Risks in Bioprocess Sampling”

2. **Semantic Keywords**:

– LSI: “single-use bioprocess connector”, “sanitary diaphragm valve accessory”

– Geo-Target: “California NSF-certified fittings”, “EU GMP sampling valves”

3. **Enhanced E-E-A-T Signals**:

– Add “Download Validation Report” CTA button

– Display compliance badge wall (3-A/FDA/ISO)

– Insert expert video explaining dead-leg elimination

—

**Rationale:**

1. **Industry-Specific Compliance**: References 3-A, EHEDG, USP, and ASME standards critical to pharma/food buyers.

2. **Material Science Depth**: Shore hardness grades, ASTM chemical resistance codes, and Ra surface metrics demonstrate technical authority.

3. **Differentiation Strategy**: Focuses on “nipple” as a sterile interface (vs. plugs as closures) with application-specific terms like “WFI”, “discharge monitoring”, “aseptic processes”.

4. **SEO Keywords**: “Sanitary sampling valve nipple”, “EPDM pharmaceutical”, “CIP/SIP compatible”, “3-A compliant”.

5. **Safety/Compatibility Notes**: Explicitly addresses media restrictions and sterilization methods to prevent misuse claims.

关于我们

宏泰专业生产高品质的卫生级阀门和不锈钢管件,主要服务于制药、食品加工和化工等行业。我们的产品采用优质 304、316 和 316L 不锈钢制成,具有出色的耐腐蚀性,并采用激光切割和精密焊接等先进制造技术精心制作而成。HongTai 的阀门专为卫生和流体完整性而设计,是要求最佳清洁度和持久性能的行业的理想选择。

为什么选择我们

质量保证: 我们严格控制从原材料到成品的每个生产阶段,确保符合 ISO9001 和国际认证,包括 3A、DIN 和 ISO 标准。

行业专长: 数十年为食品、饮料和制药等关键行业提供解决方案的经验。

先进技术: 我们拥有最先进的设备,包括定期更新的数控车床和精密工具,确保每件产品都具有较高的表面精度和较小的公差。

100% 检验: 每件产品在出厂前都要经过严格的测试,包括尺寸和阀门泄漏检测,以确保质量完美无瑕。

覆盖全球: 我们以始终如一的质量和准时交货赢得了全球企业的信赖。

选择 HongTai,您将在阀门和管件解决方案方面获得无与伦比的可靠性、性能和创新性。

联系我们

如需了解更多信息或讨论您的要求,请通过以下方式联系我们:

电子邮件:ht@htcdf.com

whatsapp:(86)18875809195

您还可以访问我们的 联系我们 页面获取更多联系方式。

评论

目前尚无评论。